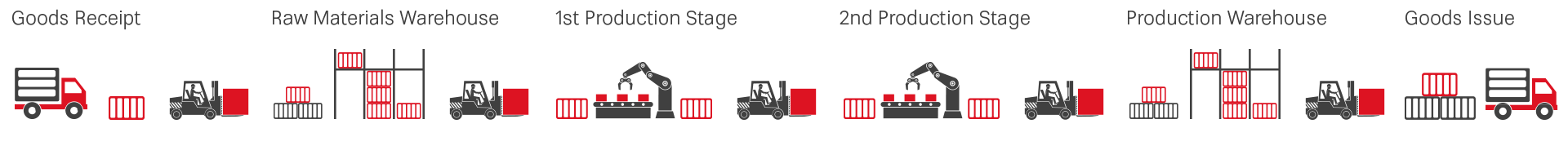

Container Management:

RFID tagged, digital load carriers bring transparency, control and management to your intralogistics

RFID-tagged load carriers provide you with

transparency about their:

- Quantity

- Location

- Status (empty, full, defective, service, etc.)

- Availability

If you "marry" the load carrier ID with the material data, you avoid errors in the material flow by plausibility checks on:

- Transport status

- Batches

- Replenishment

- Current storage location

A continuously digitalised and plausibilized data flow secures your production processes and provides error-free just-in-time deliveries of

- raw materials and semi-finished products

- at the respective production stage / per batch

- including automatic production postings

- as well as plausibility checks for the monitoring of or compliance with production processes